E8000 Offline Radial Inserter: Elevating Productivity in PCB Assembly

Our E8000 Offline Radial Inserter is engineered to automate the insertion of tape-packed components onto printed circuit boards (PCBs), enhancing efficiency and quality in PCBA (Printed Circuit Board Assembly) processes. This advanced machine supports manual PCB transfer and employs independent servo control systems to ensure high stability during component insertion, achieving exceptional results at high speeds and densities.

Key Features and Capabilities

- High Throughput Efficiency: The E8000 delivers a remarkable component placement rate of up to 24,000 components per hour (CPH), significantly outpacing manual insertion methods. It effectively manages a diverse range of radial components, including:

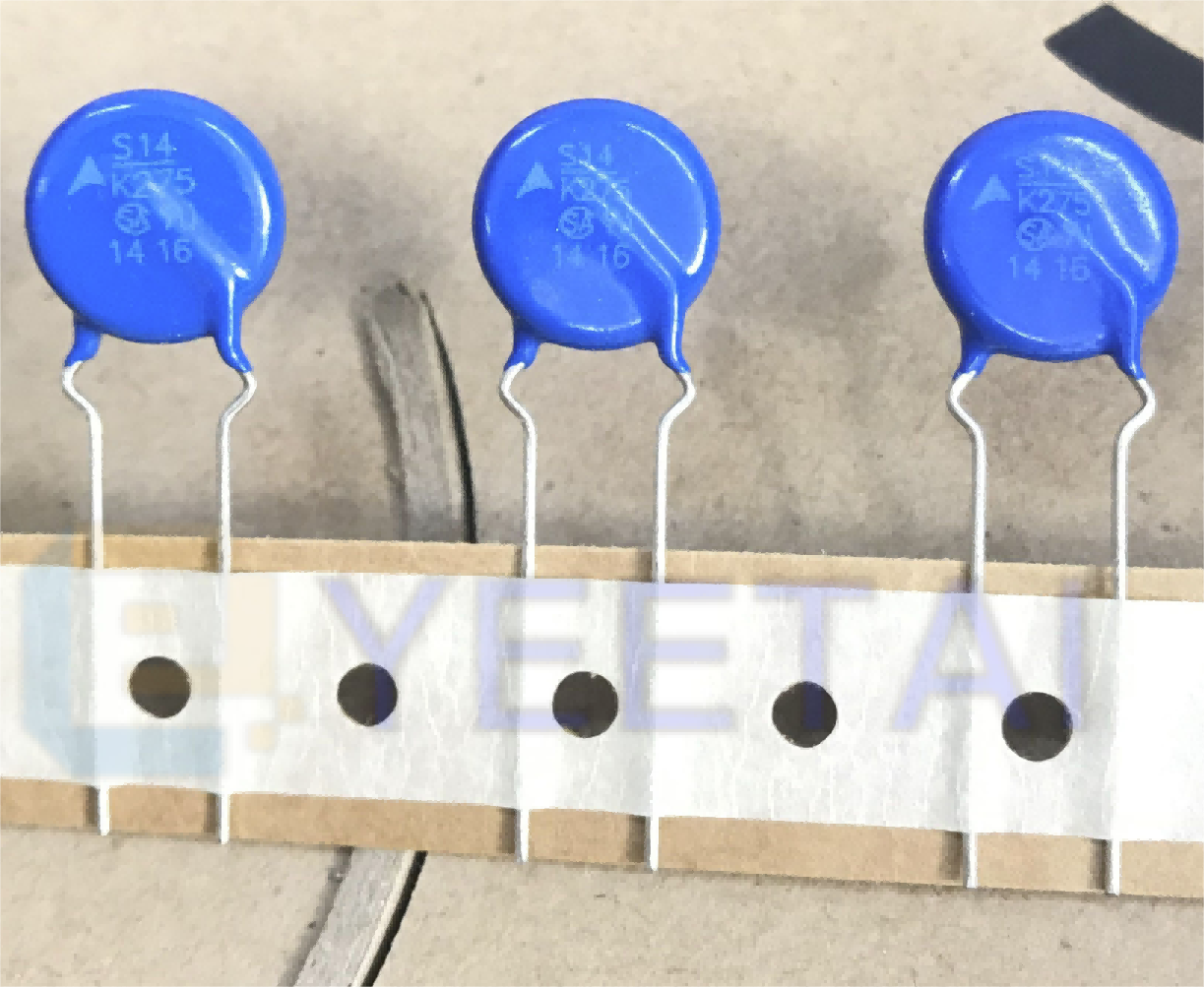

- Capacitors

- Resistors

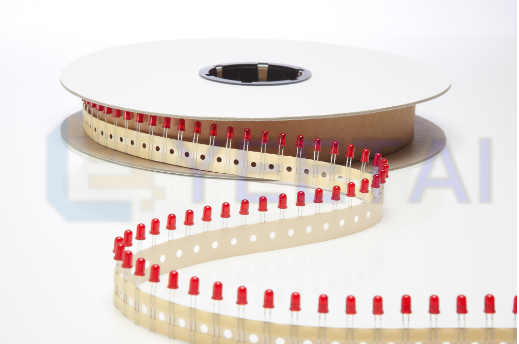

- LEDs

- Key switches

- Connectors

- Potentiometers

- Coils

- Fuse holders

- Fused wires

- Intuitive User Interface: Operating on a Windows 10 platform, the E8000 features a user-friendly interface that simplifies human-machine interaction, making it accessible for operators without complex coding knowledge.

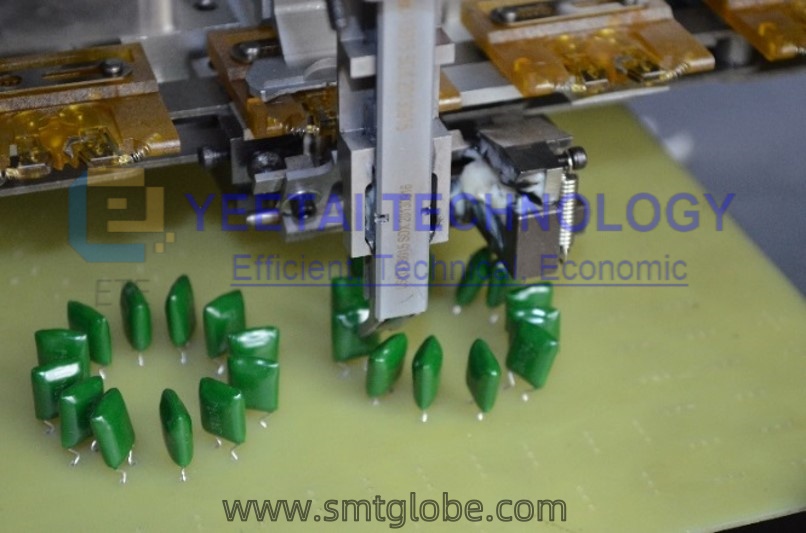

- Sophisticated Component Sequencing: The axial inserter module includes a distribution head that cuts radial components from reels or boxes, allowing for predetermined sequencing based on product programs. Components are seamlessly transferred to the insertion tool for accurate placement.

- Precision Insertion and Clinching: Upon completing the insertion process, the E8000 is equipped with a cutting and clinching unit that effectively secures component pins to the PCB, ensuring durability and reliability.

- Space-Efficient Design: The integrated body design not only optimizes operational efficiency but also minimizes space requirements, making it suitable for various manufacturing environments.

- Versatile Insertion Options: With a 360-degree rotation capability, the E8000 allows for precise positioning of components at any angle. The machine caters to a wide range of insertion spans from 2.5mm to 10.0mm, accommodating different component sizes.

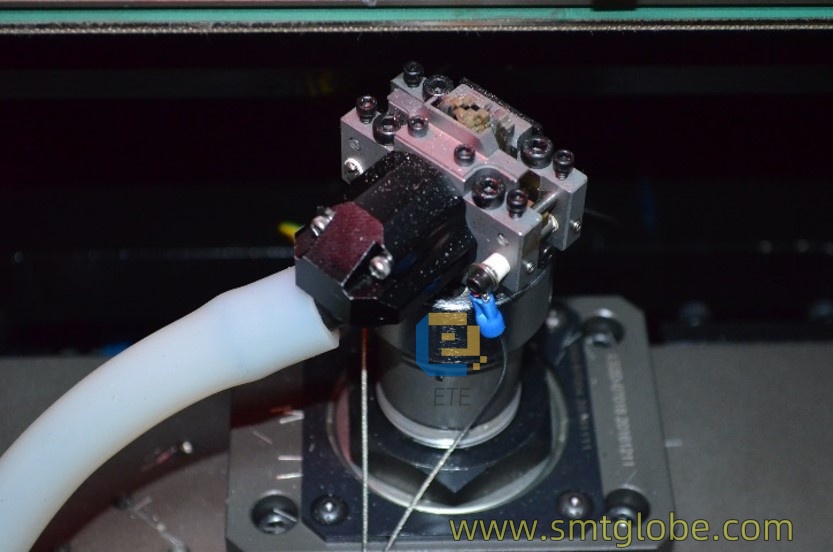

- Servo-Driven Technology: The E8000 features servo-driven insertion heads for swift, accurate component placement. Programmable worktable options and customizable feeder quantities provide a tailored manufacturing solution.

Specification

| Machine model | Radial inserter E8000 |

| Theoretical speed | 24,000 components/hour |

| Insertion direction | 0-360 degrees, 1-degree increment |

| Lead Span | Double pitch 2.5mm/5.0mm/7.5mm/3.0mm/3.5mm/10mm/15mm selectable |

| PCB Size | Minimum 50*50mm; Maximum 400*400mm |

| PCB Thickness | 0.79-2.36mm |

| Component body height | 22mm |

| Component body diameter | 12mm |

| Component type | capacitors, transistors, transistors, LEDs, key switches, resistors, connectors, coils, potentiometers, fuse holders, fused wires, etc. in radial tape package. |

| Component density | Component body distance not less than 1mm; SMD and through hole distance not less than 3mm |

| Component Lead Angle | 5-35 degrees (adjustable) |

| Feeder station | 10 / 20 stations (selectable) |

| Machine Dimension (L*W*H) | Main machine 1770mm*2078mm*1840mm ; feeding station 1200mm*1000mm*1410mm(20 stations) |

| Machine Weight | Weight of main machine 2100KG |

| Power Supply/Power Used | 220V,Ac(single-phase)50/60Hz,1.5KVA/1.6Kw(energy-saving type) |

| System protection | Built-in (USP) power failure protection power supply |

| Use of air pressure (air consumption) | 0.4-0.6Mpa/0.3 cubic meters/minute (dry gas) |

| Ambient Temperature | 5-25 degrees |

| Machine noise | 65dB |

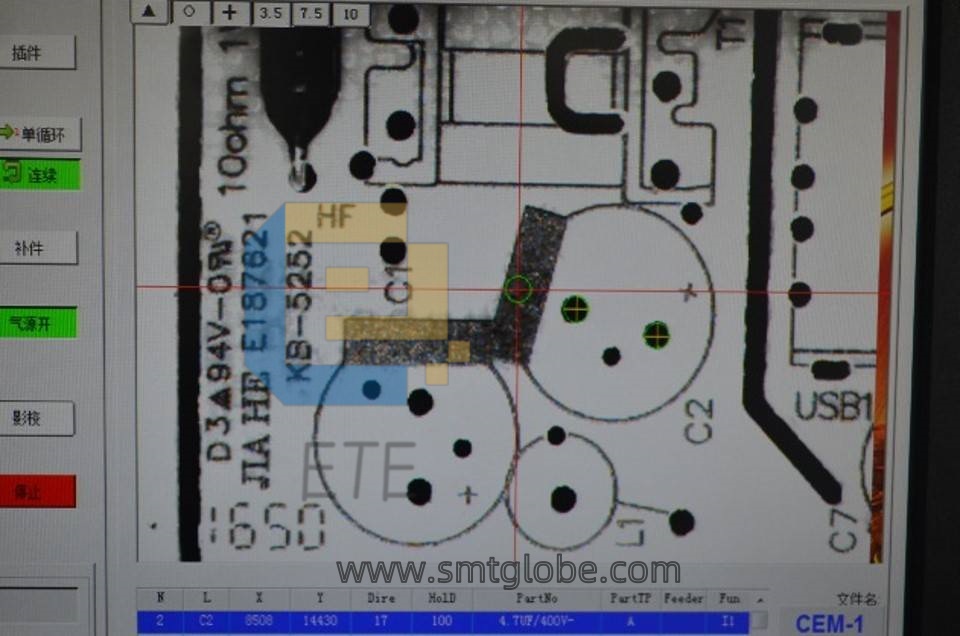

| Hole correction method | Machine vision system, multi-point MARK vision correction |

| Drive system | AC servo, AC motor |

| Data input method | USB interface input (EXCEL file format) |

| Control system | Chinese operation interface (WINDOWS XP,10 system control platform) LCD monitor |

| Table operation method | Clockwise and counterclockwise |

| PCB loading method | Manual |

| Monitor (computer) | Front and Rear |

Conclusion

The E8000 Offline Radial Inserter sets new industry standards for efficiency, reliability, and flexibility in component insertion processes. By automating the insertion of tape-packaged radial components, it boosts productivity and ensures the high quality of PCBA products. This machine is an essential asset for modern production facilities seeking to enhance operational capabilities while reducing manual labor.

If you need any more instructions on the insertion machine, we are here to help.

Guidelines for Operating a Radial Insertion Machine

How to enhance Reliability in Automatic Insertion Machines

How to boost Production Efficiency with Advanced Software for Insertion Machines

Essential Checks for Automatic Insertion Machines

Enhancing SMT Processes: Peripheral Equipment Solutions for SMT Factories

If you need more other insertion machines, welcome to our website or click below.