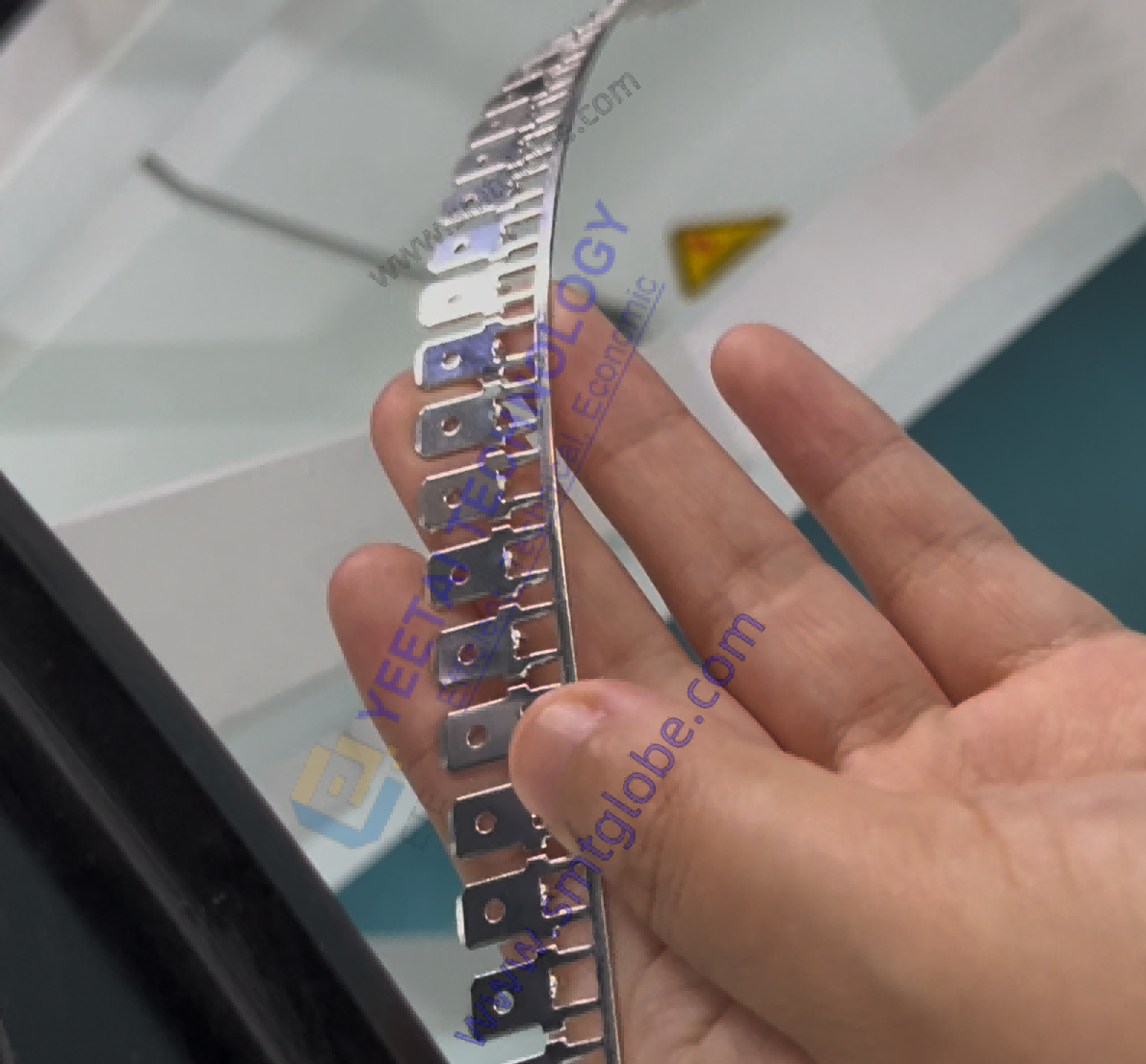

The Pin Terminal Inserter, when paired with performance-enhancing accessories, offers unparalleled flexibility to cater to a diverse range of customer needs in the PCB manufacturing industry. This advanced machine excels in inserting various pin components with different shapes and dimensions, thanks to its versatile capabilities. The exclusive feeding system is designed to handle both reel-joint packed pins and loose pins, ensuring seamless operation.

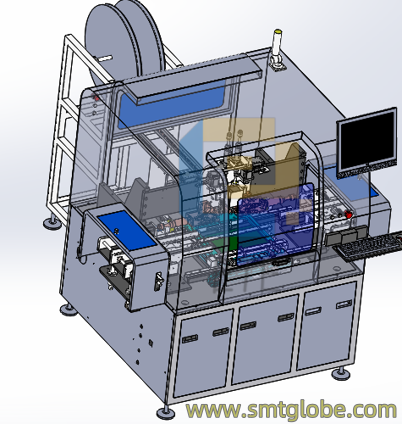

Configuration

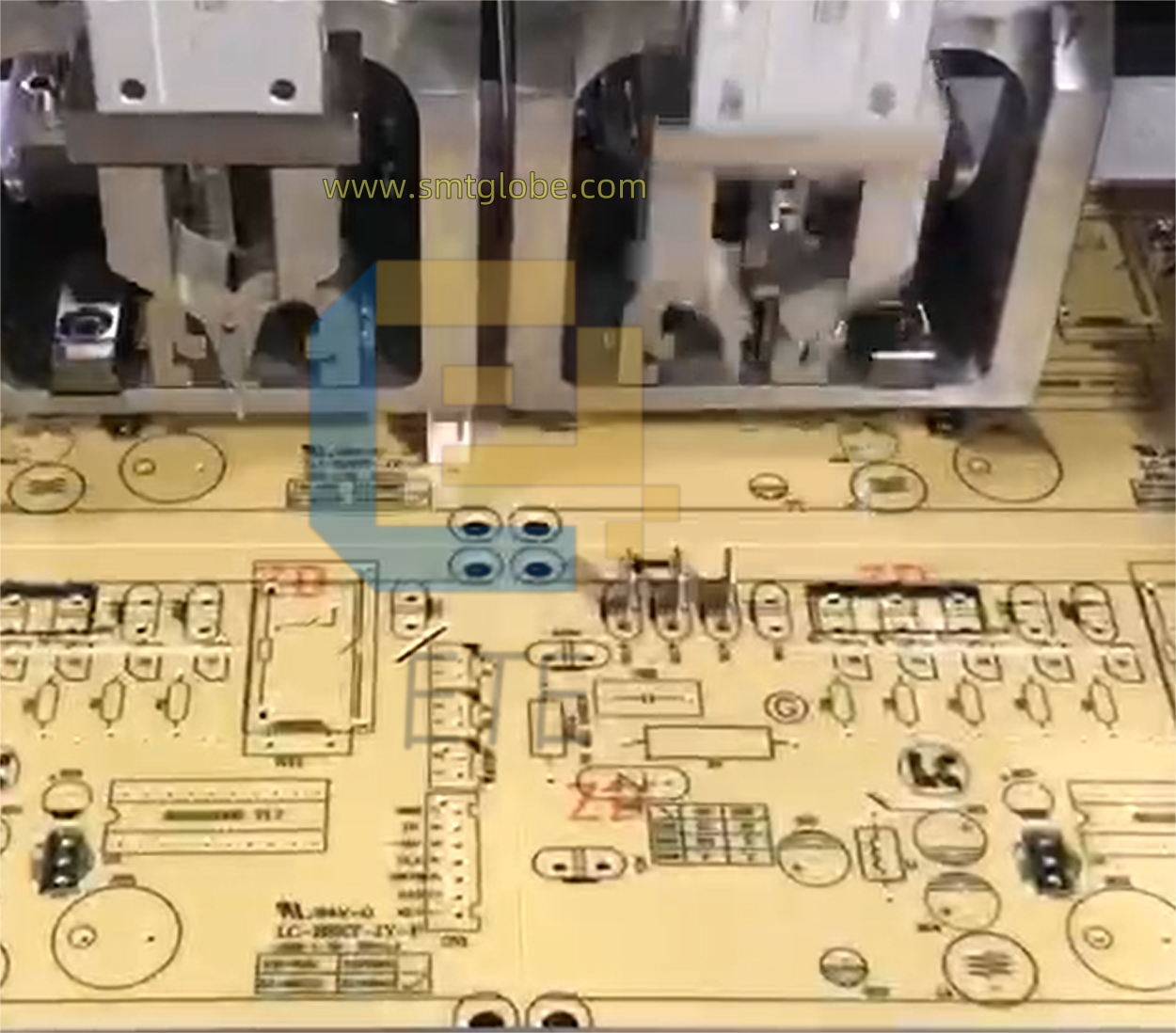

Equipped with a servo-driven insertion head, the machine guarantees precise and rapid insertion of pin components, enhancing overall efficiency. The adjustable clinching system can be tailored to meet specific process requirements, further optimizing performance. Our pin terminal inserter is renowned for delivering top-tier performance and exceptional quality across a wide spectrum of applications, making it a reliable choice for manufacturers seeking superior results.

Customization of pin terminal inserter

At our core, we are dedicated to providing tailored solutions that meet the unique production needs of our customers. Our team of Application Tooling experts is available to assist you in selecting the optimal machine configuration that aligns with your output and quality requirements. By investing in our solutions, you can achieve cost-effective production while maintaining high standards of performance and quality. Reel feeders and bowl feeders available.

Specification

| Equipment size | 1700mm*1300mm*1600mm (2 heads) |

| Machine model | pin terminal inserter |

| Packaging | Tape terminal, bulk terminal |

| Equipment weight | 1200KG |

| PCB size | 380mm*280mmm (enlarged size can be customized) |

| Number of insertion heads | 1-4 Optional |

| terminal thickness | 0.5mm ≤T≤1.2mm |

| Vertical error | ≤0.8° |

| PCB requirements | The insertion hole is 0.5±0.1mm larger than the component foot |

| Insertion angle | 360°( increment 1°) |

| Body distance | The distance between the components ≥ 2mm |

| Clinch | Inward clinching/Outward clinching/”N” |

| Humidity | 30%-70% |

| Display system | 17-inch color LCD monitor |

| Feeding system | Tape feeder or Bowl feeder + feeding guide |

| Motion accuracy | 0.001mm/pulse |

| Motion system | Panasonic controller, motor |

| Programming function | Online visual programming, visual correction, EXCEL |

| Data import | USB interface import, manual entry |

| Communication interface | RS-232C (can be connected to MES system) |

| Power | Single 220V/AC, 50/60HZ, 2KVA |

Features of pin terminal inserter

- The pin terminal inserter can be equipped with a rotary insertion finger and worktable, allowing for the application of products at various angles while maintaining a consistent insertion rate. This feature enhances flexibility and precision in the manufacturing process, accommodating diverse requirements without compromising efficiency.

- Adjusting the machine tooling is a straightforward process, facilitating quick product changeovers and minimizing downtime. This ease of adjustment ensures seamless transitions between different components, optimizing production efficiency and reducing operational complexities.

- The pin terminal inserter is equipped with advanced technology that verifies the correct insertion of each product into the PCB in real-time, providing assurance of accuracy and reliability throughout the manufacturing process. This real-time monitoring capability enhances quality control and minimizes errors, ensuring consistent product integrity.

- With insertion rates reaching up to 2 products per second at a pitch of 0.2 inches (5.08 mm), the machine offers high-speed performance for efficient production processes. This rapid insertion capability enables swift assembly of components, contributing to increased productivity and throughput in manufacturing operations.

- Pin terminal inserter can be configured with multiple insertion heads, allowing for the simultaneous application of up to 4 different components in a single machine. This multi-head setup enhances production capacity and versatility, enabling the efficient handling of diverse product requirements within a single system.

- The pin terminal inserter features the capability to store production data in the software for future traceability and analysis. This data storage functionality enables manufacturers to track and monitor production metrics, facilitating process optimization and quality control measures for enhanced operational efficiency.

- Incorporating an industrial specialized high-definition camera and automatic visual correction software, the machine ensures precise insertion through visual inspection and correction. This visual system enhances accuracy and reliability in component placement, guaranteeing consistent and high-quality results in PCB assembly processes.

- The pin terminal inserter applies low stress on the PCB during the insertion process, safeguarding the integrity of the circuit board and delicate components.

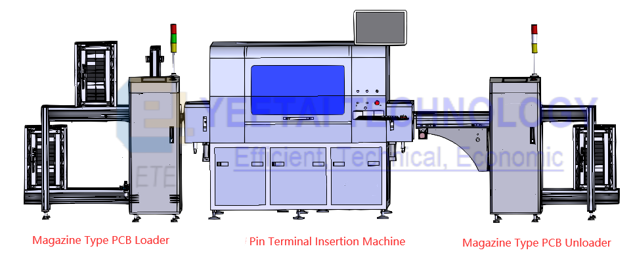

- Being SMEMA compatible, the machine can establish communication with neighboring machines, enabling seamless coordination and data exchange within the production line. Additionally, it can be integrated with an automatic board handling system to efficiently load and unload PCBA to and from other machines, enhancing workflow automation and throughput.

- With MES compatibility, the machine allows for the uploading of production data to the SMT factory MES system for monitoring, management, and traceability. This integration enables real-time data sharing and analysis, facilitating comprehensive oversight of production processes and ensuring traceability of components throughout the manufacturing cycle.

Full line solution

If you need more other insertion machines, welcome to our website or click below.