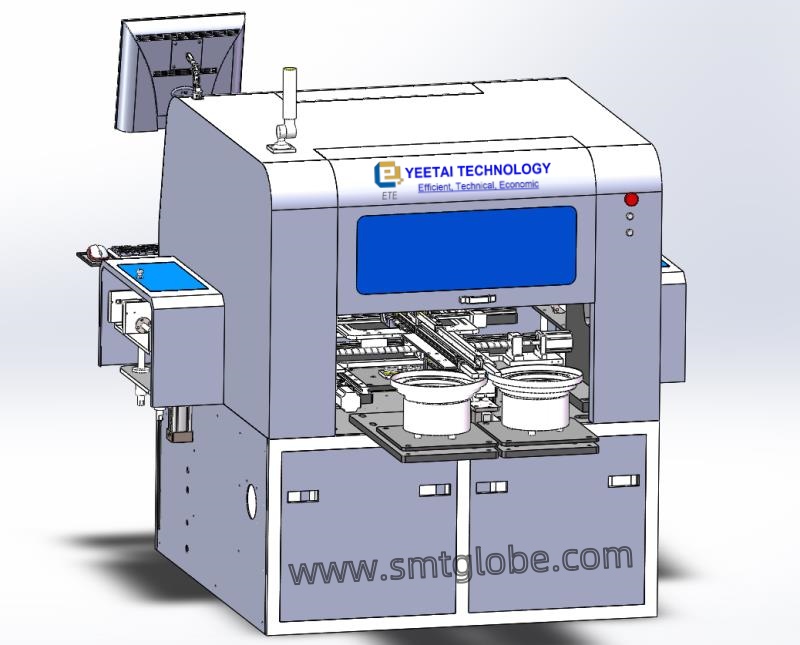

Pin Terminal Insertion Machine: Revolutionizing PCB Manufacturing

Our Pin Terminal Insertion Machine is a cutting-edge solution which meets the diverse needs of the PCB manufacturing industry. When paired with performance-enhancing accessories, this advanced machine excels in inserting various pin components, accommodating different shapes and dimensions efficiently.

Key Features and Benefits of pin terminal insertion machine

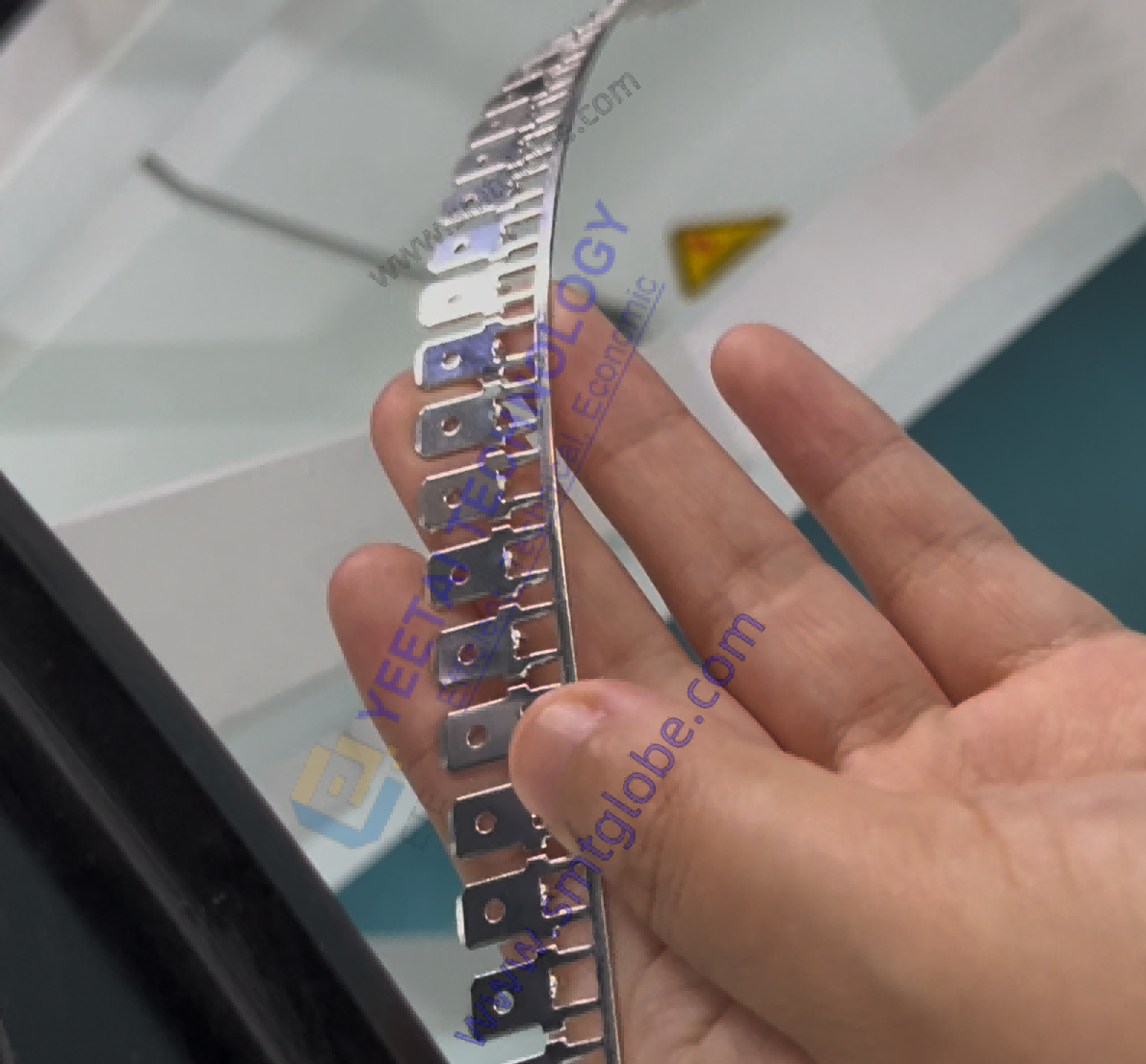

- Versatile Feeding System

- The exclusive feeding system handles both reel-joint packed and loose pins, ensuring seamless operation for a wide range of applications.

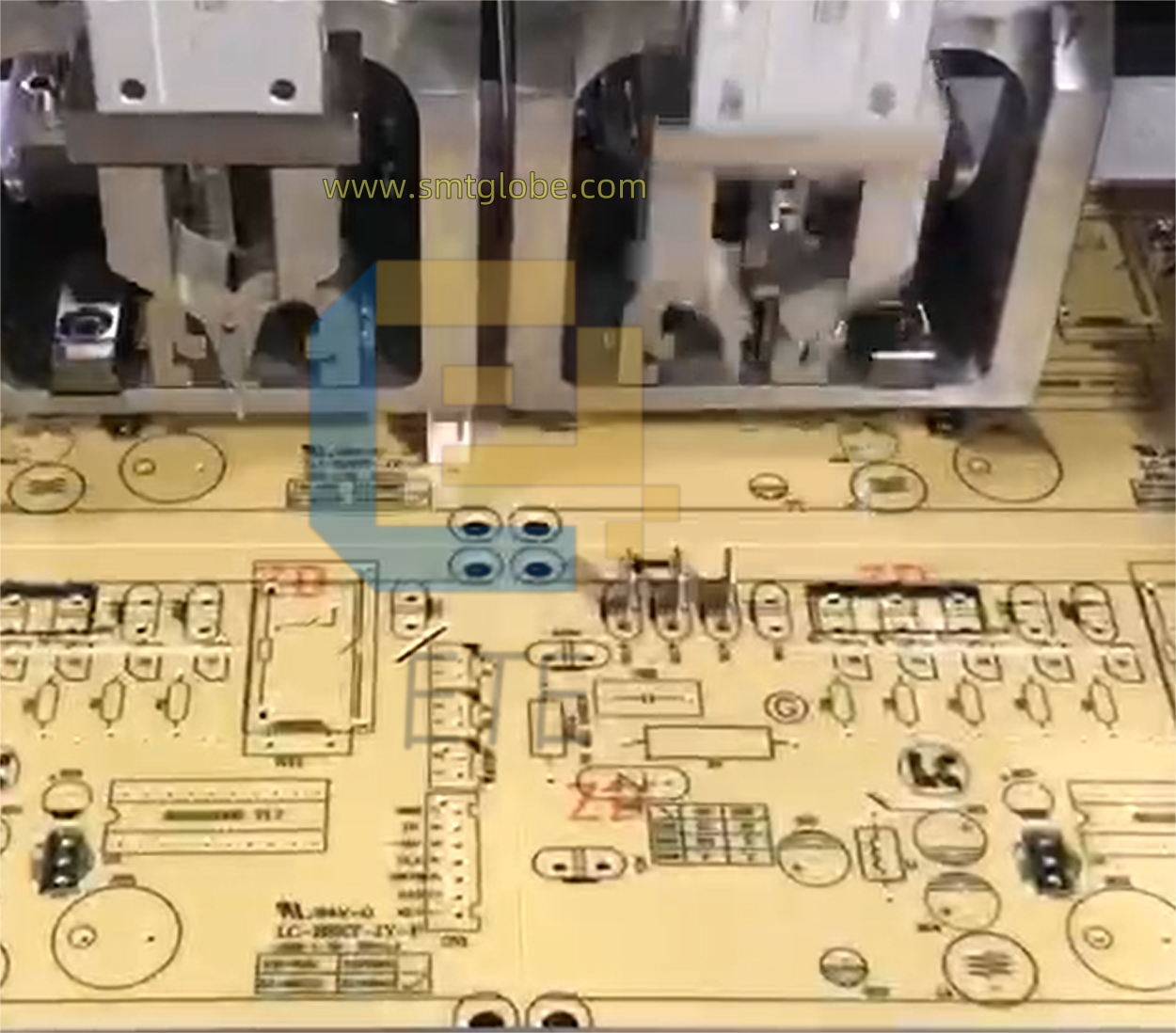

- High-Precision Insertion

- Equipped with a servo-driven insertion head, our machine delivers precise and rapid insertion of pin components, significantly enhancing overall efficiency.

- Adjustable Clinching System

- Tailor the adjustable clinching system to meet specific process requirements, optimizing performance for your unique production needs.

- Rapid Insertion Rates

- Achieve insertion rates of up to 2 products per second at a pitch of 0.2 inches (5.08 mm), enabling swift assembly of components and increased productivity.

- Multi-Head Configuration

- The machine can be configured with multiple insertion heads, allowing the simultaneous application of up to 4 different components within a single system, enhancing versatility.

- Real-Time Monitoring

- Advanced technology verifies the correct insertion of each product into the PCB in real-time, ensuring accuracy and reliability throughout the manufacturing process.

- Data Storage and Traceability

- Store production data in the software for future analysis and traceability, facilitating process optimization and quality control.

- Visual Inspection Technology

- Incorporating an industrial high-definition camera and automatic visual correction software, the machine guarantees precise insertion and high-quality results through visual inspection.

- Gentle Handling

- Apply low stress on the PCB during the insertion process to safeguard the integrity of the circuit board and delicate components, minimizing the risk of damage.

- SMEMA and MES Compatibility

- Being SMEMA compatible, the machine establishes communication with neighboring machines for seamless coordination. Additionally, it integrates with an automatic board handling system and uploads production data to the SMT MES system for effective monitoring and traceability.

Specification

| Equipment size | 1700mm*1300mm*1600mm (2 heads) |

| Machine model | Pin Insertion Machine ET6000 |

| Packaging | Tape terminal, bulk terminal |

| Equipment weight | 1200KG |

| PCB size | 380mm*280mmm (enlarged size can be customized) |

| Number of insertion heads | 1-4 Optional |

| terminal thickness | 0.5mm ≤T≤1.2mm |

| Vertical error | ≤0.8° |

| PCB requirements | The insertion hole is 0.5±0.1mm larger than the component foot |

| Insertion angle | 360°( increment 1°) |

| Body distance | The distance between the components ≥ 2mm |

| Clinch | Inward clinching/Outward clinching/”N” |

| Humidity | 30%-70% |

| Display system | 17-inch color LCD monitor |

| Feeding system | Tape feeder or Bowl feeder + feeding guide |

| Motion accuracy | 0.001mm/pulse |

| Motion system | Panasonic controller, motor |

| Programming function | Online visual programming, visual correction, EXCEL |

| Data import | USB interface import, manual entry |

| Communication interface | RS-232C (can be connected to MES system) |

| Power | Single 220V/AC, 50/60HZ, 2KVA |

Safety Precautions

Safety is paramount when operating the Pin Terminal Insertion Machine. Before setup, please adhere to the following guidelines:

- Read the Operation Manual: Familiarize yourself with the equipment’s operations and safety information.

- Receive Proper Training: Ensure that all operators are trained and understand safe handling and operational protocols.

- Note the Safety Signs:

- Danger Signs: Indicate hazardous events; failure to comply may result in serious injury.

- Attention Signs: Highlight potential personal injury or equipment damage from improper operation.

- Prohibition Signs: Clearly mark operations that are absolutely forbidden.

Unpacking Instructions

To safely unpack your machine, follow these steps:

- Place the machine on a flat, spacious surface.

- Open the packaging cover carefully, avoiding excessive force.

- Remove the front and back packing plates.

- Carefully take off the left and right packing plates.

- Use a forklift to lift the machine from the front bottom center.

- Remove the bottom packing plate once the machine is lifted.

- Once the machine is securely positioned, remove any film packaging and fastenings.

If you require more information or a user manual, please contact us. Our team can provide step-by-step instructions to ensure a smooth setup process.

Contact Us

Ready to enhance your PCB manufacturing processes? Contact us today to learn more about our Pin Terminal Insertion Machine and how it can meet your production needs with superior performance and flexibility!