E8040 is an offline axial component insertion machine that operates independently. It provides manual PCB transfer and automatically inserts components supplied on tape into printed circuit boards (PCBs). This machine features independent sets of servo control systems that ensure high stability in component insertion performance, achieving perfect results at high speeds and densities. Its application software is based on the Windows XP system, with a simple and user-friendly interface that facilitates human-machine interaction. The Axial Component Insertion Machine enhances efficiency in component insertion and the quality of PCBA products. It primarily consists of three main functions: “Component Sequencing and Feeding,” “Component Insertion,” and “Component Lead Cutting and Forming.”

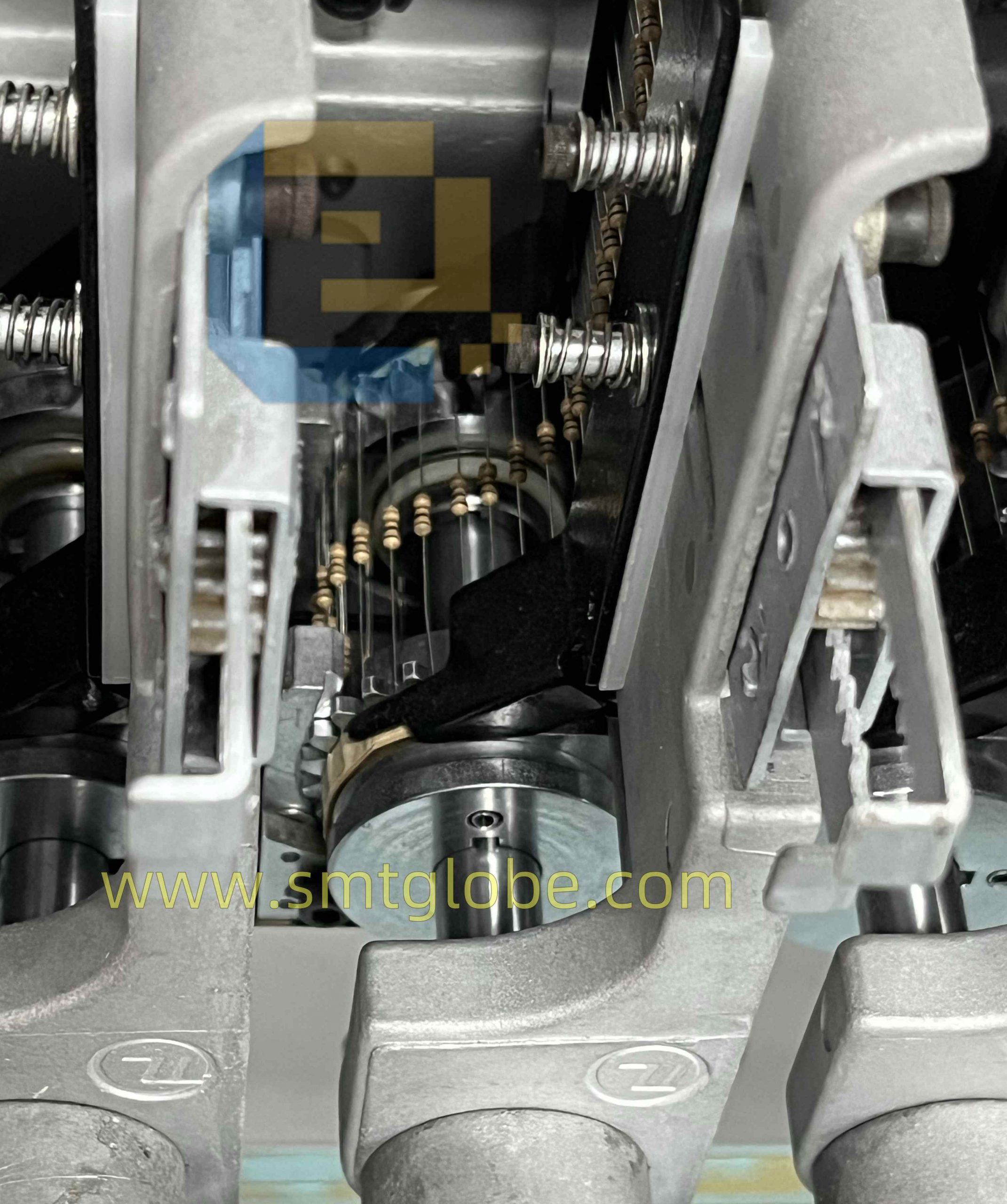

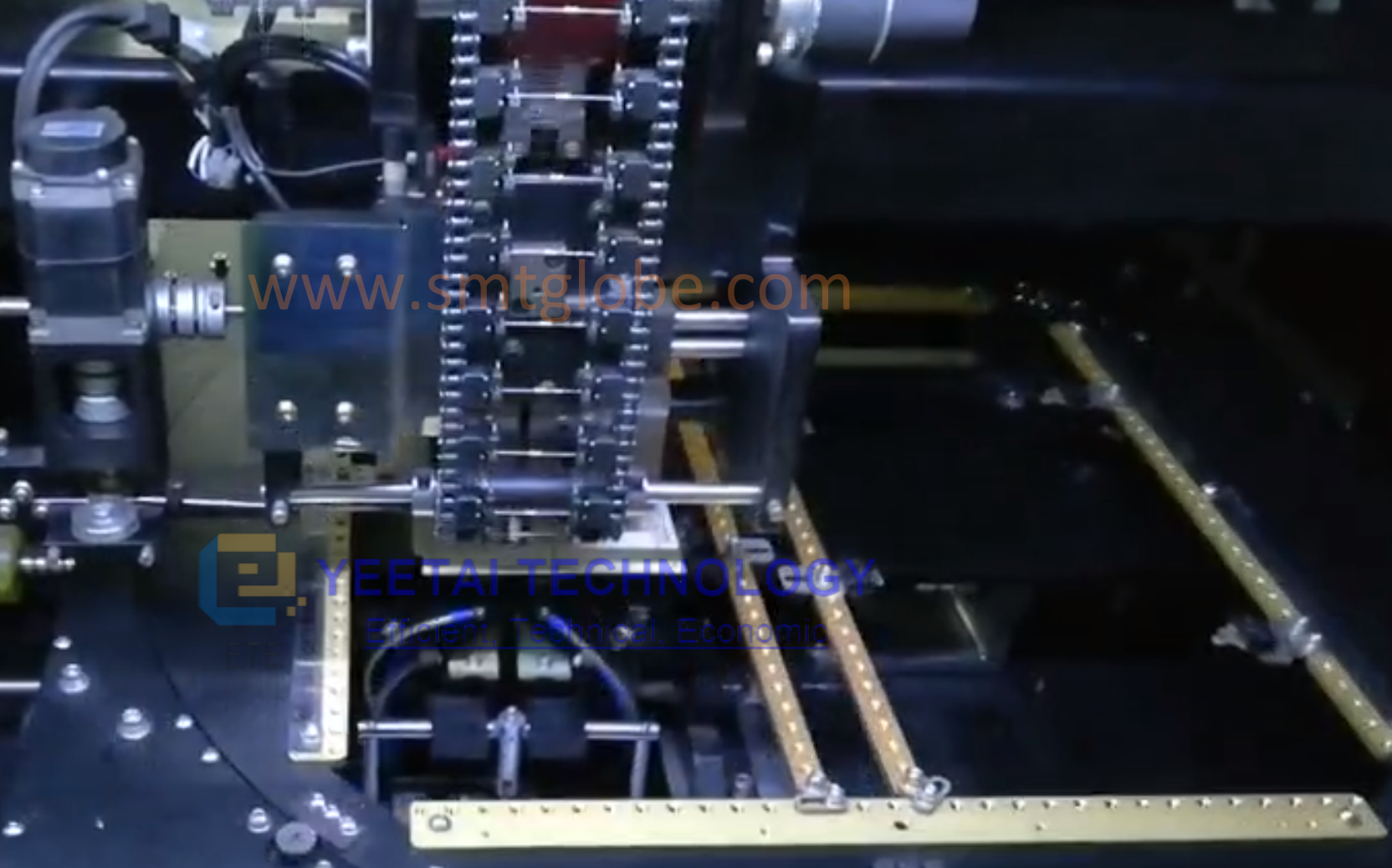

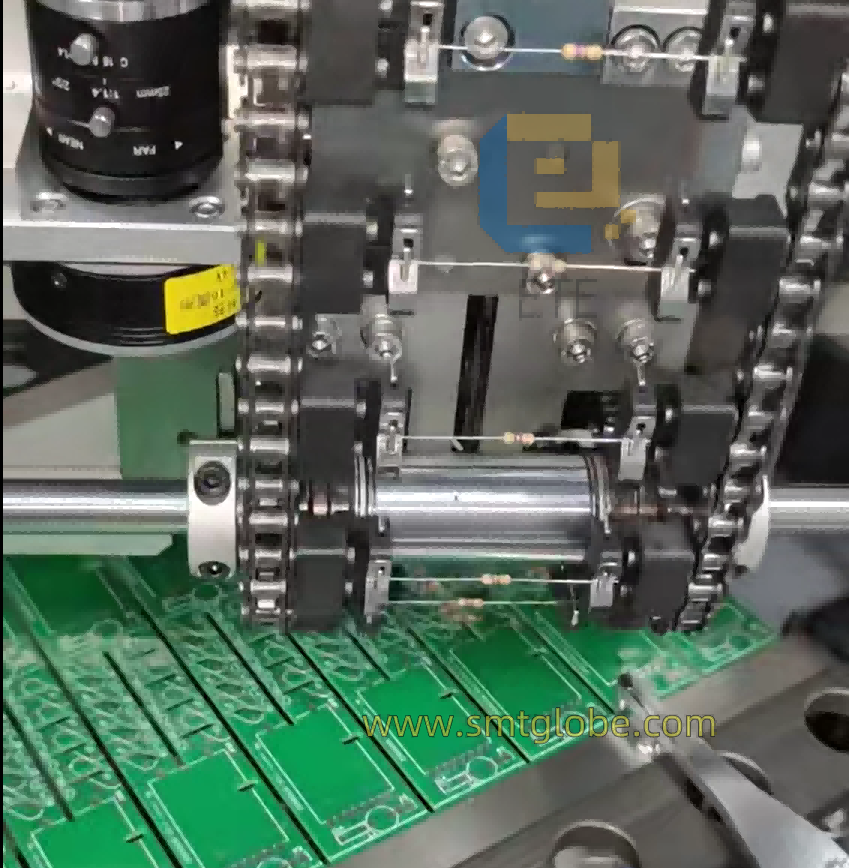

The Component Sequencer and feeder function involves modules of the axial insertion machine that include a distribution head for cutting horizontal components from reels or trays and placing them on the sorting machine chain. The sequence of components is predetermined by the product program. The components are then transferred to the head chain for delivery to the insertion tool, with the program controlling the position and direction of component insertion.

For Component Insertion, a product program is created with information related to the components, PCB board, and processing requirements. Once this product is called upon, the operation of the axial insertion machine can begin.

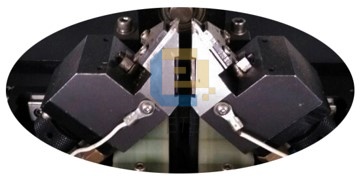

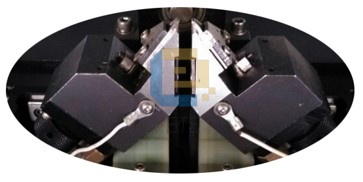

After fully inserting into the PC board, the cutting and clinching unit of the axial insertion machine cuts and forms the component pins mechanically (clinching) to secure them to the board. This process continues until the product is completed, and all required horizontal components are in place. When the program is finished, the PCB is either removed from the machine or transferred.

Specification

| Machine model | E8040 |

| Theoretical speed | 24,000 components/hour |

| Insertion direction | Parallel 0 degrees, 90 degrees, 180 degrees, 270 degrees |

| Lead Span | Double hole spacing 5-20mm |

| PCB Size | Minimum 50*50mm; Maximum 450*450mm |

| PCB Thickness | 0.79-2.36mm |

| Component Type | Capacitors, transistors, diodes, resistors, fusible wires, etc. Braided tape encapsulation material |

| Jumper wire | Independent conveying method. Diameter 0.5mm-0.8mm tinned copper wire |

| Component Lead Cutout Length | 1.2mm-2.2mm (adjustable) |

| Component Lead Angle | 5-35 degrees (adjustable) |

| Machine Dimension (L*W*H) | Main machine 1700mm*1500mm*1800mm ;feeding station 2100mm*1000mm*1410mm(20 stations) |

| Machine Weight | Weight of main machine 2100KG;Weight of sub-machine 480KG |

| Power Supply/Power Used | 220V,Ac(single-phase)50/60Hz,1.5KVA/1.6Kw(energy-saving type) |

| System protection | Built-in ( USP) power failure protection power supply |

| Use of air pressure (air consumption) | 0.4-0.6Mpa/0.3 cubic meters/minute(dry gas) |

| Ambient Temperature | 5-25 degrees |

| Machine noise | 65dB |

| Hole correction method | Machine vision system, multi-point MARK vision correction |

| Drive system | AC servo, AC motor |

| Data input method | USB interface input (EXCEL file format) |

| Control system | Chinese operation interface (WINDOWS XP system control platform) LCD monitor |

| Table operation method | Clockwise and counterclockwise |

| PCB loading method | Manual |

Features:

The Axial Component Insertion Machine boasts proprietary tooling with a high-efficiency and stable feeding drive structure. It offers expandable and precise sequencing capabilities along with component feeding that ensures zero jumper lead scrap. With its flexibility and precision, the machine can insert a full array of axial lead components and jumper wire diameters in a single operation.

Setting an industry benchmark, it achieves the highest real throughput of 24,000 components per hour (CPH) and boasts world-class reliability at 300 parts per million (ppm). The programmable clinch height feature of the Axial Component Insertion Machine safeguards against damaging surface-mount device (SMD) components, while also verifying component value and polarity before insertion.

Enhanced by a Rotary Table, the Axial Component Insertion Machine is equipped with long-life tooling and low-profile locators that reduce wear and extend operational lifespan. Its low maintenance requirements and user-friendly programming interface, facilitated by a USB port for data transfer and support for Gerber format (Excel) file input, ensure efficient and swift operations.

Moreover, the machine is equipped with built-in power failure protection (USP) and allows for component replenishment without halting operations. It also features a dual-part detector that can sense two parts on the chain simultaneously, enhancing operational efficiency and reliability.

Advantages of the Axial Component Insertion Machine:

- Replaces manual labor with automated operations.

- Achieves a theoretical speed of 24,000 components per hour.

- Offers simple operation and high stability for consistent performance.

- Enables flexible production deployment with versatile capabilities.

- Features low maintenance costs, ensuring cost-effective operation.

More insertion machine as below.